Ground loops in HVAC sensor wiring can be a real nuisance because they are hard to spot. Most of the time they do no harm but they can cause unpredictable problems years after the installation.

A ground loop is formed when there is more than one conductive path between the “ground” terminals on two or more pieces of equipment. The conductive loop forms a large loop antenna that picks up interference currents easily. The larger the loop, the more interference. If you are using the building’s steel frame for your ground, then the loop can be as large as the whole building. The resistance in the ground wires turns the interference currents into voltage fluctuations in the ground system. This makes the system ground unstable, and because the signals you are trying to measure are referenced to that ground as well, those signals become unstable and inaccurate.

The following five examples are ways that you can avoid or minimize the effect of ground loops in your installations.

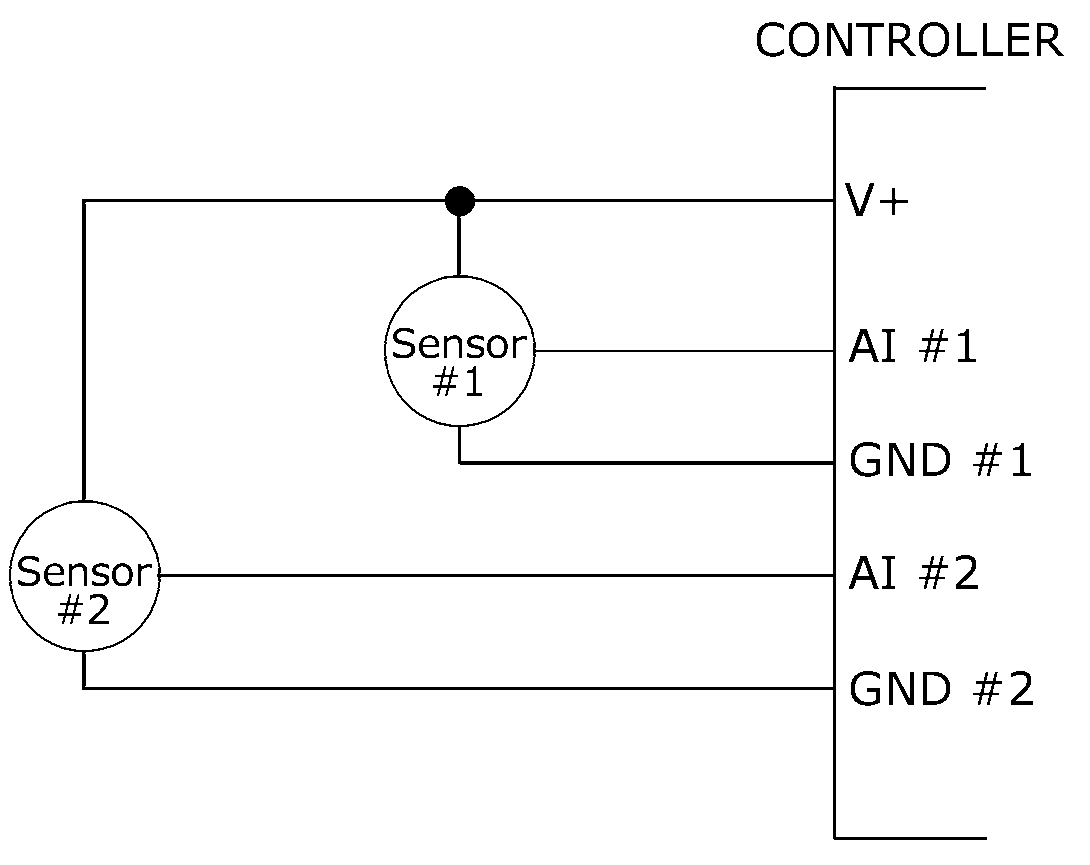

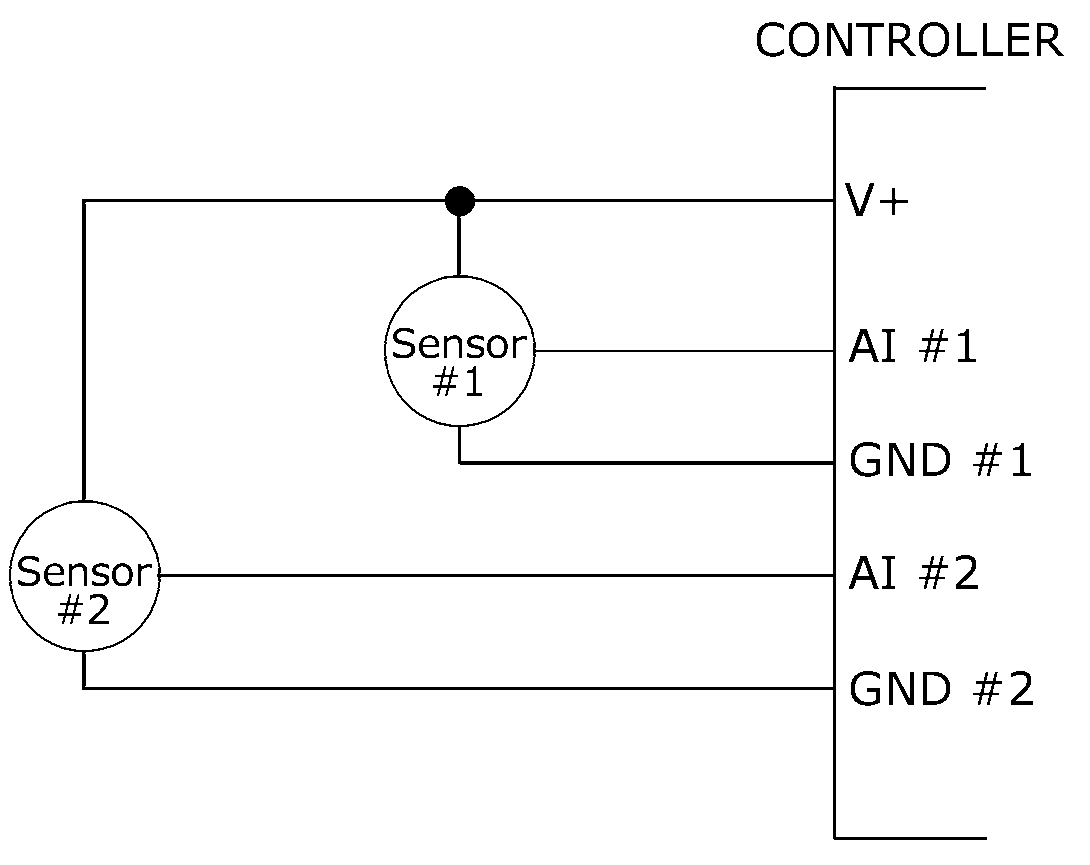

1. DON’T SHARE GROUNDS

The ground wires from a sensor should not be shared with any other sensor or power load (see Figs 1 & 2). When a ground wire is shared between two sensors, the current from the first sensor will interfere with the signal of the second sensor.

2. MINIMIZE LOOP AREA WITH TWISTED PAIR WIRING

The potential for ground loop interference can be greatly reduced by minimizing the loop area of the conductors between the sensor and the controller. The easiest and most effective way to reduce loop area is with twisted pair wiring which works by cancellation. Each twist acts as a small loop antenna, but after the next twist, the loop is reversed so the interference from the second loop cancels the interference from the first.

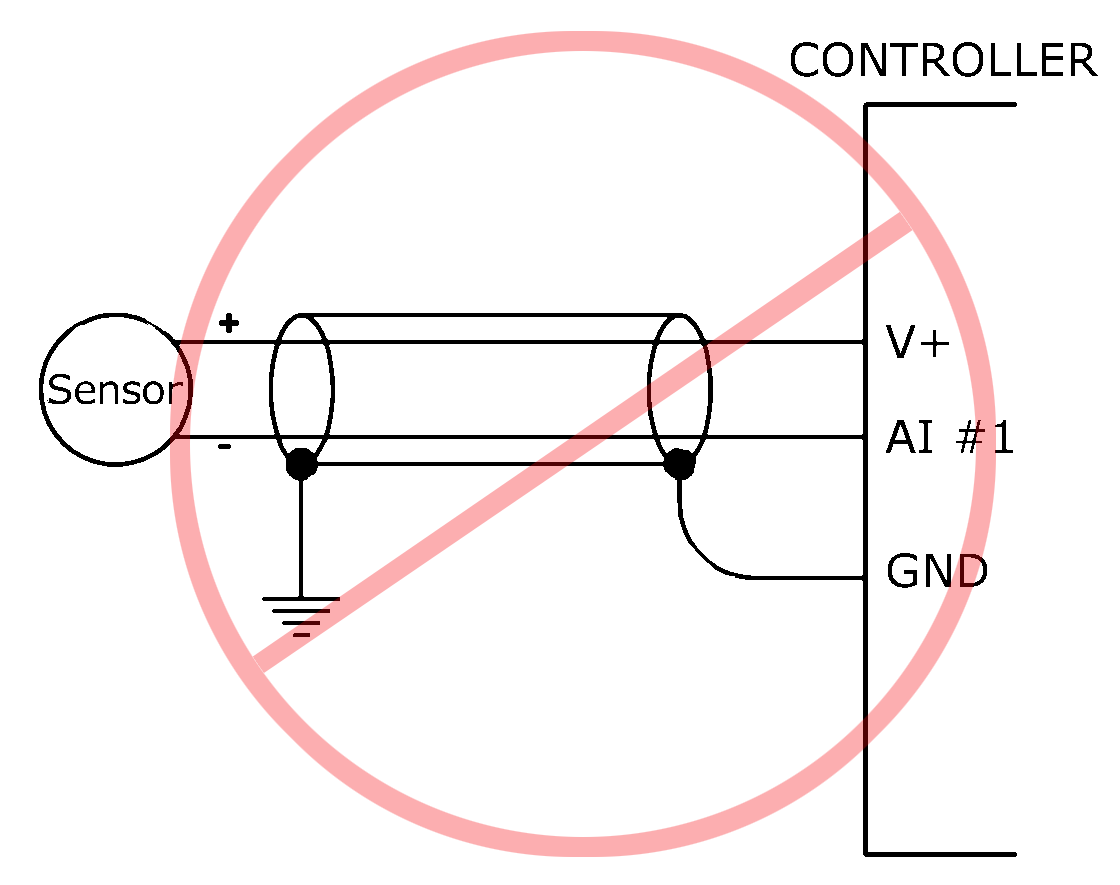

3. DON’T GROUND REMOTE SENSORS

If a sensor is placed more than one inch from a controller, only ground the sensor to the ground terminal on the controller which is associated with the analog input you are using (see Figs 3 & 4). Do not ground a remote sensor to building steel or to the power system ground at the remote mounting point. If the sensor’s case must be grounded for safety, isolate the case from the sensor and ground each separately.

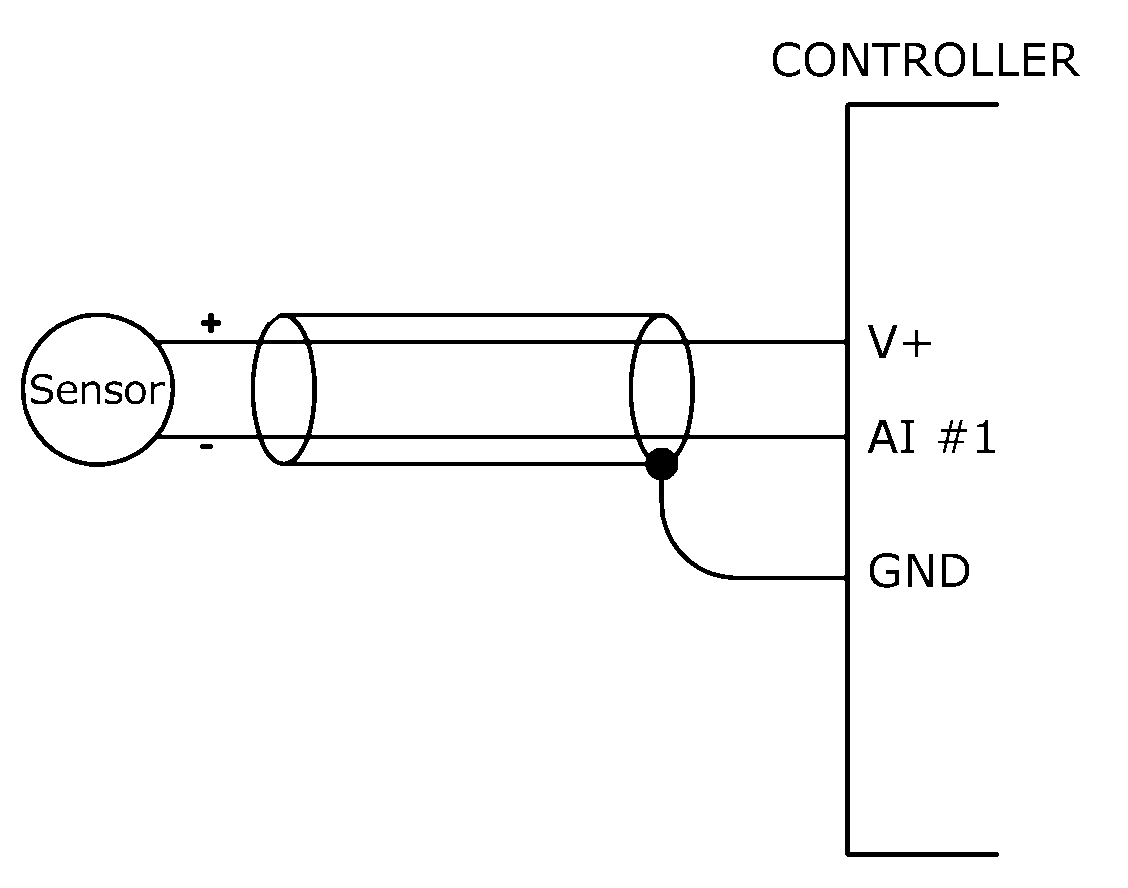

4. USE SHIELDED WIRE GROUNDED ONLY TO THE CONTROLLER

In very electrically noisy environments, shielded cable may have to be used (see Figs 5 & 6). The shield prevents electrical fields from penetrating the wire. The shield should only be grounded at the controller end. If the shield is grounded at both ends, a ground loop will occur.

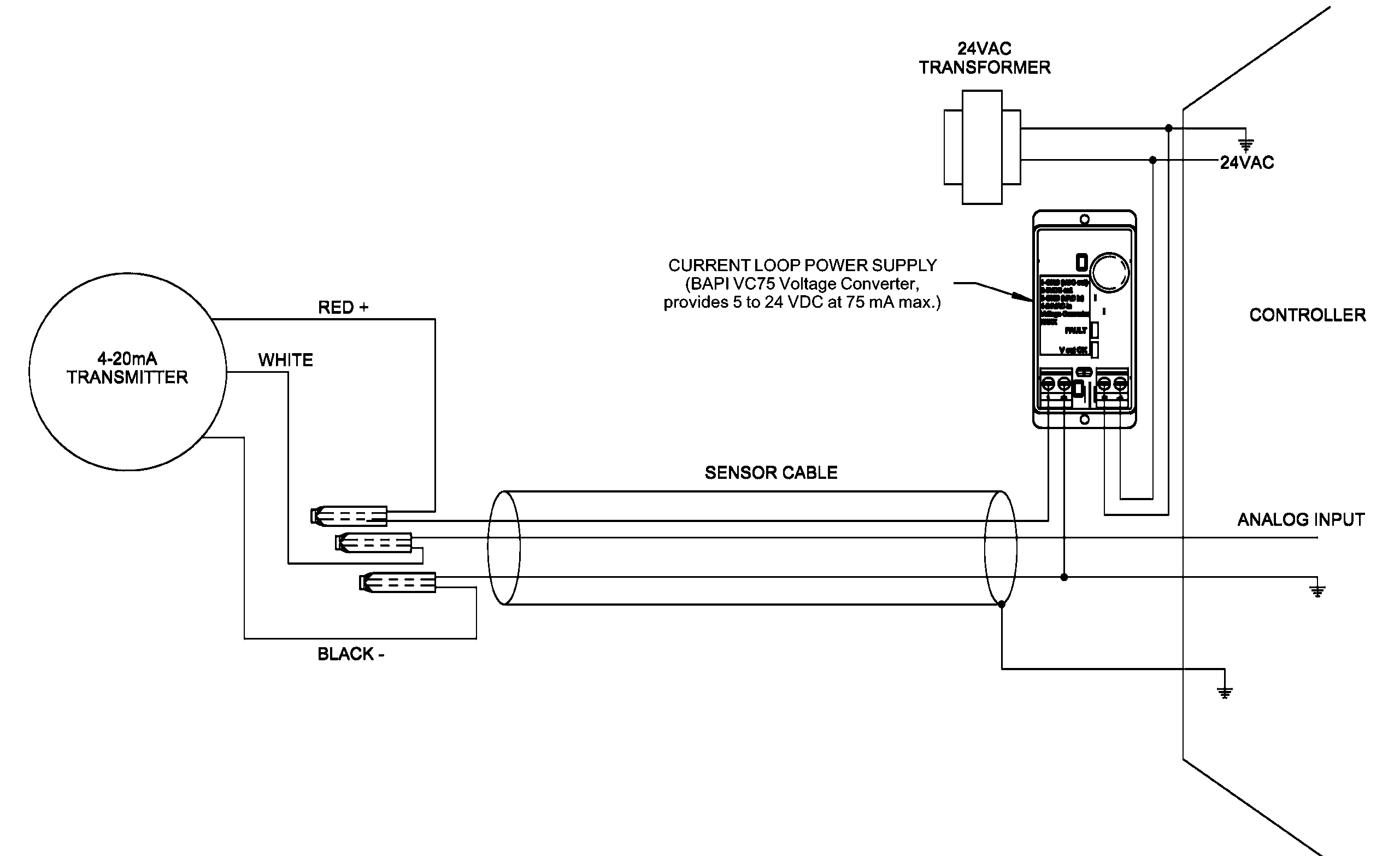

5. PLACE AUXILIARY POWER SUPPLIES AS CLOSE AS POSSIBLE TO THE CONTROLLER

Auxiliary power supplies used to power three-wire sensors should be placed as close as possible to the controller (see Fig. 7). Ideally the auxiliary power supply should be grounded through the controller.

Note: Many controllers have DC voltage available to drive transmitters. If your controller has this DC voltage available, and the remote sensor does not overload the controller voltage supply, you may not need the external power supply shown in Fig. 7.

If you would like more in depth information about ground loops, call your BAPI representative or see the BAPI Application Note: “Understanding Ground Loops” on this website

References

ANSI/NFPA 70, National Electric Code 2002 – National Fire Protection Association

CONSTRUCTION STRATEGIES FOR MINIMIZING STRAY VOLTAGE ON DAIRY FARMS, Michigan State University

Henry Ott, Noise Reduction Techniques in Electronic Systems, 2nd edition, Wiley and Sons, NY, NY, 1988